Screw Spike

The screw spike, also called rail screw, it can be used to fasten the ribbed base plates and sole plates to wood sleepers. It can be used to fasten the SKL Clip to rails and will obtain high clamping force. It has better fixing power than rail spike or dog spike, which lead to it’s widely using in many fastening system.

Screw Spike

Application for Screw Spikes in SKL System

| Item | Component | Types | Material |

|---|---|---|---|

| 1 | Rail Clip | SKL1, SKL3, SKL14, SKL21 | 60Si2MnA |

| 2 | Screw Spike | Ss25, Ss35, DHS35, Ss8, etc | 35K/Q235 |

| 3 | Rail Dowel | Sdu9, Sdu25, Sdue S3 | HDPE/PA6 |

| 4 | Angle Plate | Wfp14k, Wfp21k | PA6+30%GF |

| 5 | Rail Pad | Zw600, Zw700 | EVA/TPU |

| Types | Photos | Technical Specifications |

|---|---|---|

Ss series sleeper screw |

|

Types: Ss1/130, Ss1/150, Ss2/180, Ss5/150, Ss6/150, Ss7/180, Ss8/150, Ss25/160, Ss35/160, etc. Grade: 4.6, 5.6, 8.8, 10.9 Material: Q235, 35K, 45#, 40Cr, etc. Surface: Plain, Zinc, HDG, Color Painted, etc. |

3V Sleeper screw |

|

Types: V20-135, V23-115, V23-135, V23-155, V23-215, V26-115. Grade: 4.6, 5.6, 8.8 Material: Q235, 35K, 45#, etc. Surface: Plain, Zinc, HDG, Color Painted, etc. |

Double Head Screw Spike |

|

This is to fixes the rail together with the Nabla clip system. Mostly used in Europe and Africa.To meet the strict bending requirement, special raw material is applied by straightening it without any crack after bending 30 degrees or even more. |

Sleeper Screw for wooden sleeper |

|

Standard: AREMA Size: 15/16×6-1/2” Material: 45# Tensile Strength: ≥120,000psi Surface: Plain (oiled), Color painting, Zinc, HDG, ect. |

Rail sleeper screws with big disk |

|

Market: South America Size: Diameter: 22mm &23mm; Length: 115mm&133mm&178mm Material: Q235, 35#, 45# Surface: Plain (oiled), Color painting, Zinc, HDG, |

With over 20 forging machines, we are able to offer various Screw Spikes.

Our advantages:

- Advanced production equipment, mature production technology and perfect quality assurance system

- High production volume, able to produce with the fastest speed.

- Mature management system with lowest cost, which guarantee the quality stability.

- Competitive price with best service.

Do You Have A Railway Project We Can Help With?

GK RAILWAY

GK Group, is an enterprise manufacturing railway fasteners, whose products cover fields of railway, urban rail, mining, etc.

There are two factories located in Zhangzhou Fujian and Anyang Henan, which are all CRCC and ISO certificated, with a total area of about 320,000 ㎡, workers over 300, and an annual sales volume of over RMB 200,000,000.

Founded in 1960, With over 50 years of specializing in railway fasteners, GK has served many demanding markets worldwide, including USA States, Chile, Argentina, Ecuador, Brazil, Thailand, Indonesia, Malaysia, Vietnam, Spain, Italy, Romania, England, Kazakhstan, etc.

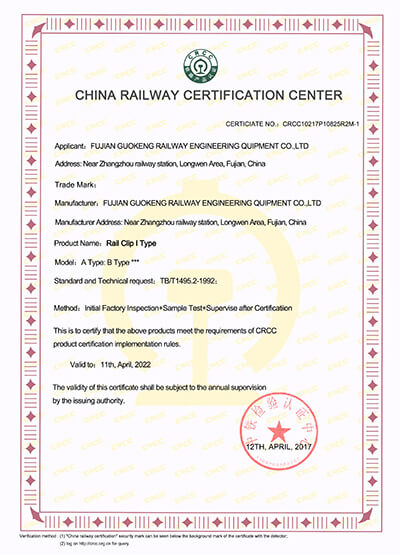

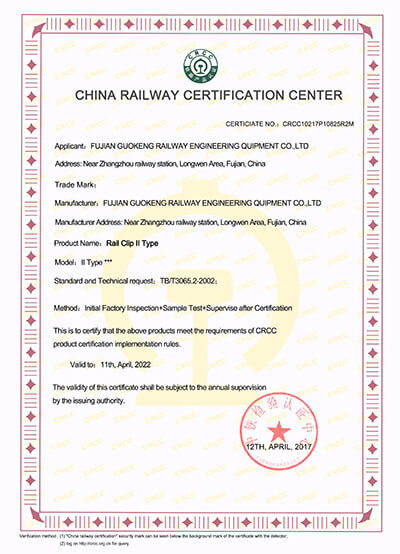

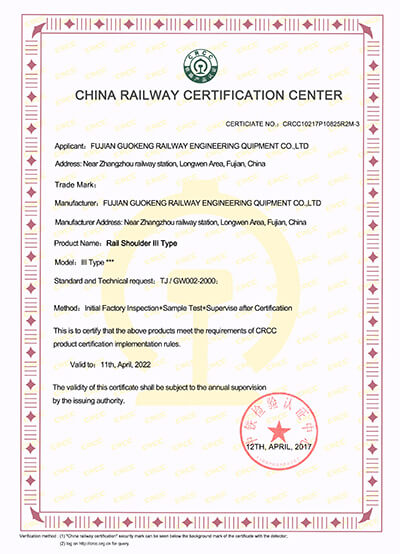

Our Certificates

With ISO and CRCC certificated, Guokeng tries its full efforts to save cost for each client by upgrading our Production Equipment & Inspection Facility & Quality Management System to be more efficient, economy, and also with good quality control capacity. Quality and reliability are always our culture. We will never stop upgrading and developing, and will spend our whole life in delivering best quality and service.